20

Years Of Working Experience

M/s.JRS INDUSTRIES was promoted on June 12, 2013 in the New Ancillary Unit, M/s. JRS Industries employers are technically qualified & well experienced engineers in fabrication, engineering & assembly section. JRS organization have adequate experience in the Field of Heavy Fabrication of Mild Steel Parts to M/s.BHEL, Ranipet

360° Experience

JRS prides itself on offering customers from a wide array of industries a truly turnkey experience. The company has invested in its manufacturing facilities to ensure clients receive reliable, well-conceived and well-made systems.

Why choose JRS?

Our Mission - We have made it our mission to provide excellent crafted and high sustainable system and Heavy Duty Fabrications to various industries and power generators, cement , steel , fertilizer industries.

We have the widest experience in heavy duty fabrication of ESP , Material handling conveyors , ID & FD Fans , Dust handling Systems, Heavy duty columns etc

Our products are developed by talented and passionate people. Every day we strive to make it easy for our customers to always choose JRS industries . Sharing this passion is in our DNA and we are proud to make a difference.

Our People - We take pride in developing long lasting relationships that are mutually beneficial with the proverb “Always Come to JRS First”!

General Fabrication

General fabrication is the process of constructing items from different parts using a variety of materials and processes. It is often associated with metal fabrication, which involves using processes like cutting, bending, welding, stamping, and assembling to create metal structures.

- Designing: The project is designed

- Cutting: There are many ways to cut sheet and plate metal

- Forming: The metal is formed

- Assembling: The parts are assembled

- Finishing: The item is finished

- Installing: The item is installed

- Maintaining: The item is maintained

Here are some steps involved in the fabrication process:

Fabrication can be done manually, but it is often automated using computer aided designs (CAD) and computer numerical control (CNC) technologies. These technologies can reduce costs, lead times, and material usage while improving accuracy and quality.

Heavy Duty Process Fans

Industrial fans are heavy-duty ventilation systems designed to move large volumes of air, improving airflow and cooling in factories, warehouses, and other industrial environments. They help maintain optimal working conditions and enhance equipment efficiency.

Dust Handling Systems

A bag filter is a dust collection system that uses fabric bags to trap and filter airborne particles from industrial air streams. It helps maintain air quality and prevent contaminants from escaping into the environment.

Electrostatic Precipitators

Electrostatic precipitators are air pollution control devices that use electrical charges to remove dust and other particles from industrial exhaust gases. They help improve air quality by efficiently capturing fine particulate matter.

Air Intake Systems

Air intake systems are designed to filter and deliver clean, cool air into engines or industrial processes. They enhance performance, efficiency, and longevity by preventing contaminants from entering critical components.

OUR VALUABLE CUSTOMERS

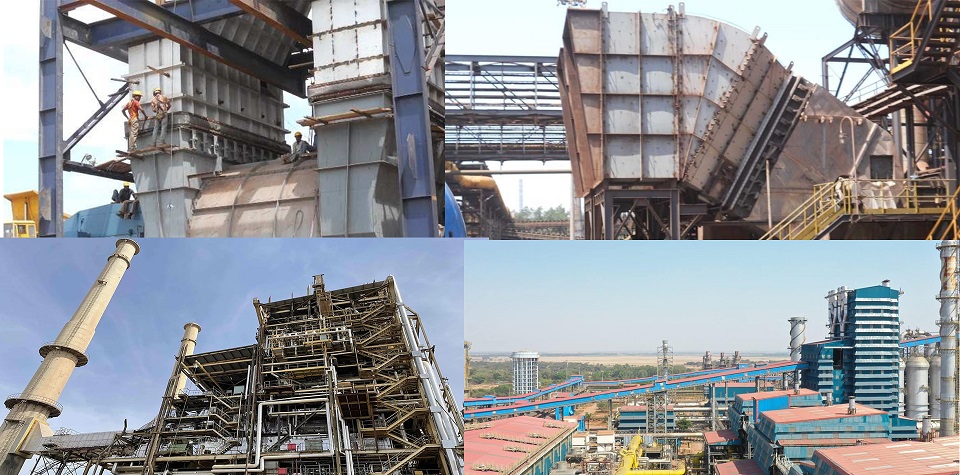

OUR PORTFOLIOS

Our Latest Projects

Our Activities

The followings activities are carried out during the work experience

Raw Material Planning

Efficient raw material planning ensures optimal inventory levels, reduces costs, and supports uninterrupted production. Streamline your supply chain with data-driven strategies for reliable operations and growth..

Procurement & Inspection

Streamline procurement and ensure quality with our expert inspection services. Reliable solutions tailored to meet your needs, guaranteeing efficiency, compliance, and excellence every time.

Production Planning

Streamline your fabric production with precision. Expert planning ensures efficiency, quality, and timely delivery for all your textile needs. Your trusted partner in fabric manufacturing

In-process Inspection – Stage and Fit-up Inspections

Welcome to our website, where innovation meets reliability in providing top-notch industrial solutions. Explore our range of products designed to enhance efficiency and performance for your business needs.

Internal Inspection

Ensure top-notch quality with our internal inspection services. We specialize in fabric evaluation, detecting flaws, and maintaining production excellence for ultimate customer satisfaction.

Final Inspection

Ensure quality and precision with our meticulous final inspection services. We guarantee flawless fabrics that meet the highest industry standards, ready for market success.